In grade 316L or 904L,STARFLEX is a double skin, smooth bore stainless steel flexible multi-fuel flue liner. This range is perfect for the renovation of existing masonry chimneys with offsets, for multi-fuel and wood burning stoves.

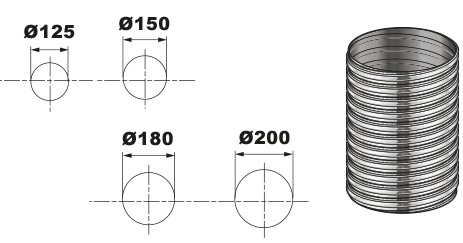

It is available in 4 diameters (Ø125, Ø150, Ø180 & Ø200) and can be supplied in 3 different packaging methods: Cut lengths, Ecofilm coils and de-coiling box.

> Incredibly strong and extremely flexible.

> Quick and easy to install with no mess.

> Low resistance to flow.

> High resistance to corrosion.

> Wide range of accessories i.e. Cowls, Register Plate, Adjustable Elbows, brackets & supports

Complete range of ancillaries available

> Air-vent, fire-cement, fire rope, smoke pellet, mastic, sealant, CO alarm, paint, insulation bag, thermometer, moisture meter, clay pot and more.

All of the products offered by Cheminées Poujoulat have been rigorously tested in every configuration by the CERIC Laboratory to ensure they meet highest standards (Building Regulation Document J - Amendments to Approved Documents).

> Max. Temperature limitation: 450°C

> CE marking: 0071-CPR-22012

> Designation:

> 316L STARFLEX: T450 P1 W Vm L50012 G - thickness: 2 x 0.12mm

> 904L STARFLEX: T450 P1 W Vm L70010 G - thickness: 2 x 0.10mm

PACKAGING METHODS

> Cut Lengths: It can be ordered in 8,10,13 & 16 metres, it is wrapped in bubble wrap and shrink wrap eco-film to ensure maximum protection during transportation.

> Cut Lengths Totems: 3 to 4 cut lengths mounted on a «totem» pallet for easy storage.

> Ecofilm Coils: From 44 to 31 metres coils depending flex diameter, it can be packed as 1 coil shrink wrapped on one pallet or be supplied with 2 coils on one pallet.

> De-coiling Box: Perfect for vans, you can pull out and cut off the length required without un-wrapping the complete coil

Lining an existing stack

> An old existing masonry chimney usually requires relining, the masonry on its own isn’t very well adapted for safe evacuation of combustion gases coming from a heating appliance. Indeed, the existing stack liner can be too old and failing, too large and its tightness can no longer be guaranteed. The solution is to reline it with our Starflex stainless steel liner.

> Your existing unlined masonry chimney can be at risk of domestic fires, increase in condensation, reduction in chimney draught. It is essential, to optimise the operation of your chimney, by re-lining it using the right flexible liner, guaranteed, conformed and safe, and add a chim-wrap insulation to further improve performance of chimney and the appliance.

> > The lining principle consists of inserting into the existing stack in one continuous piece, a CE Marked 316L or 904L corrosive resistant multi wall stainless steel flexible liner connected to your appliance flue pipe for the evacuation combustion gases.

Why should I insulate my chimney ?

> For any appliance to work correctly the chimney has to draw into the appliance air for "combustion to work successfully", the draught pressure is created by the difference in temperature from inside the liner to the outside ie. the flue must be kept warm. The larger the difference in temperature between the flue gasses and the air outside the larger the draught and the better appliance works.

Do I need to insulate my chimney ?

> For chimneys that run up through the inside of the house, the house provides insulation and it is usually not necessary to insulate the liner at Poujoulat we suggest that chimneys running up a chimney on a gable wall or exposed outside walls should be insulated to counter the cooling effect of the outside wall, we would also recommend that the section of liner in the part of the masonry chimney exposed above roof level should also have insulation wrap added for the same reason.

Why should I use 904L Flex?

> When burning some types of coke and solid fuels the smoke and gasses produced can carry very aggressive corrosive elements. If the air supply to the appliance is closed down and the stove allowed to slumber this causes incomplete combustion a reduction in flue gas temperature and an increase in pollution and the concentration of corrosive elements is greatly increased and can mix with condense to form acids, which can dramatically reduce the life expectancy of any stainless steel liner. At the same time the increased soot and tar build up can also lead to a chimney fire. 904L grade stainless steel has a little higher anti-corrosion resistance than 316L stainless steel when using these types of fuel and bad appliance operation and can provide an improved longevity to the liner. However the best way to avoid corrosion is not to slumber the appliance, burn wood with less than 20% MC and regularly service and sweep the appliance and chimney.

Sweeping

> It is important that chimneys serving all types of solid fuel appliance are swept regularly to remove soot, tar corrosive elements and avoid potential blockages. Hetas recommend a minimum once per year sweeping for occasional use and twice a year for more regular use.